The process of welding cardboard to plastic requires precision tools and appropriate technology. The key role here is played by the sealer machine and the suitably prepared carton, which is covered with a special varnish or plastic layer that enables the blister material to be bonded to the carton, creating durable, aesthetically pleasing and functional packaging. In the manufacturing industry, and particularly in the packaging sector, the welding of these two components produces robust products that meet customers’ expectations in terms of quality and protection of the goods. Sealed packaging is often used in products that require additional protection, such as electronics or pharmaceuticals, which makes this technology crucial in a wide range of sectors.

How does the sealer machine work?

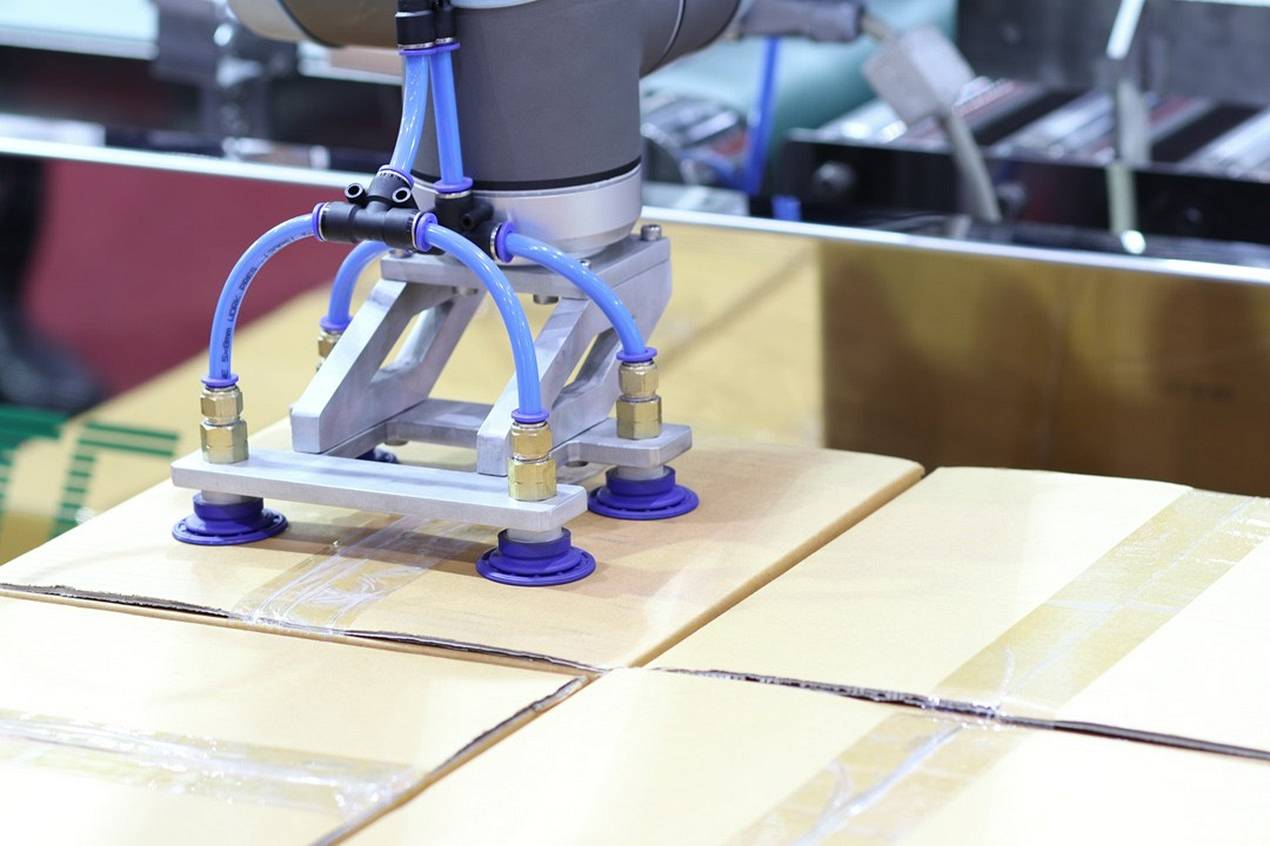

The basis of the sealing process is the use of a heat sealer machine or a high-frequency sealing machine. In the case of high-frequency welding, the bonding process is carried out using an electromagnetic field generated by high-frequency alternating current. The electromagnetic field generated in this way connects the cardboard to the plastic. This process is extremely efficient due to the use of electromagnetic waves, which heat the materials at the point of contact, allowing them to be permanently bonded. Most importantly, the technology allows packaging to be produced quickly and economically in large batches, while maintaining the high quality of the final product. Thanks to the precise settings of the machine, it is also possible to adapt the pressure and temperature to specific materials, giving full control over the quality of the seal.

High-frequency welding works well with a variety of materials, and the flexibility of this technology enables the production of both simple and more complex designs. The sealer machine ensures process stability while allowing its parameters to be adapted to specific requirements, which makes it an indispensable tool in many industries. In addition, automation of the entire process significantly minimizes errors and reduces production costs, which is beneficial from the perspective of manufacturing companies.

Application of sealer machines

Sealer machines are widely used in a variety of industries, including the automotive, pharmaceutical and also packaging industries. They are ideal for the production of covers, tarpaulins and also blister packaging, where a permanent connection between the carton and the film is essential. Zemat Technology Group offers state-of-the-art machines that guarantee the highest quality of welded products thanks to their advanced technology and precise execution. Thanks to their versatility, production lines can be quickly adapted to changing market needs.

Welding cardboard to plastic is not only a method of effectively joining materials, but also a way of creating packaging that stands out in terms of both aesthetics and functionality. This process makes it possible to produce highly durable packaging, which is important for an industry where both product protection and attractive appearance are important. Thanks to the development of sealing technology, the packaging can be more environmentally friendly and the production process itself even more sustainable.