3D printing opens up new possibilities for us to create items that previously required a complex manufacturing process or were hard to come by. This revolutionary technology allows for the transformation of digital designs into three-dimensional, physical objects.

In this article, you will learn how to start your 3D printing adventure and what you can print in the comfort of your own home. We will look at the basic steps necessary to begin, the types of printers available, and inspiring ideas for home projects.

What is 3D printing?

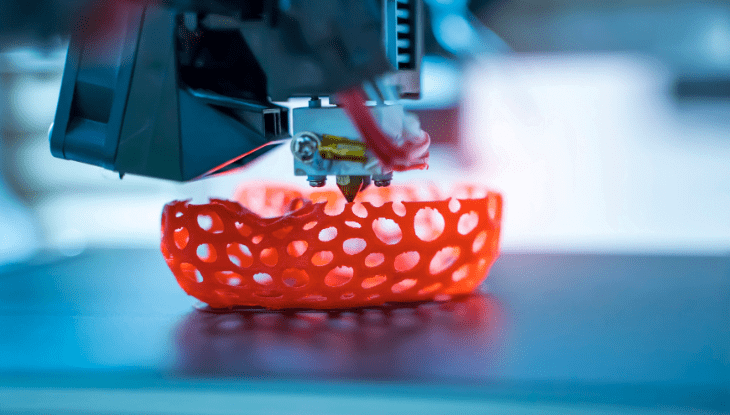

3D printing is a production process in which material is layered upon itself to create a three-dimensional object. It is an additive method, meaning the object is built up from scratch. In contrast to subtractive methods, where material is removed, for example through cutting or milling.

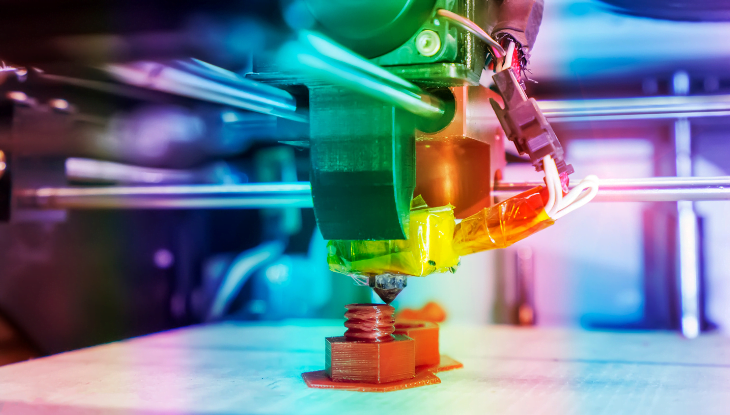

3D printers can use various materials, such as plastic or metal, and a variety of techniques. All enable the transformation of digital files containing three-dimensional data created with computer-aided design (CAD) or computer-aided manufacturing (CAM) software, or with a 3D scanner, into physical objects.

This innovative process opens up new possibilities in various fields, from prototyping to producing finished parts and products. With 3D printing, creating complex projects that would be difficult or impossible to achieve with traditional methods becomes more accessible and cost-effective.

Who invented 3D printing?

The first 3D printer using stereolithography was created by Charles W. Hull in the mid-1980s. For a long time, stereolithography was associated with expensive commercial technology, where machines reached prices of five or even six figures. However, recent years have brought significant changes.

Professional desktop stereolithographic printers have appeared on the market, now costing just a few thousand dollars. Consumer systems are also emerging, with prices starting at less than a thousand dollars. This opens the door to a wider use of this technology, both in professional applications and by hobbyists and in homes.

How does it work?

3D printing operates on principles similar to traditional printers, but it utilises various technologies. The most well-known method is fused deposition modelling (FDM), also known as fused filament fabrication (FFF).

In this filament technique, made of acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), or other thermoplastics, melts and is layered by a heated extruder nozzle. The first 3D printers available on the market, created in the mid-90s by Stratasys in collaboration with IBM, used FDM technology. Similar to most 3D printers designed for consumers, hobbyists, and schools.

Another technology used in 3D printing is stereolithography. Here, a UV laser shines into a tank of UV-sensitive photopolymer, drawing the object on its surface. The polymer hardens in the areas touched by the laser, and the beam “prints” the object layer by layer according to the instructions from the CAD or CAM file.

There is also a method of 3D printing using digital light processing (DLP) projector, which involves exposing liquid polymer to light from a DLP projector. The polymer hardens layer by layer until the object is built, and the remaining liquid polymer is drained off.

Multicolour inkjet technology is a 3D printing system similar to inkjet printers, which sprays colourful, glue-like binder onto successive layers of powder, where the object is formed. It is one of the fastest methods, and one of the few that allows for multicolour printing.

What are the benefits of 3D printing?

3D Printing offers designers the opportunity to quickly transform ideas into three-dimensional models or prototypes, also known as “rapid prototyping”. This allows for rapid changes to be made in the projects.

Manufacturers can produce goods on demand rather than in large batches, which streamlines inventory management and reduces the need for large warehouse space. People in remote locations can create items that would otherwise be impossible for them to access.

From a practical point of view, 3D printing enables financial and material savings compared to subtractive techniques, as it uses significantly less raw material. This heralds a change in the nature of production, ultimately allowing consumers to download files for printing. Even complex three-dimensional objects, including electronic devices, can be produced at home.

What can 3D printers create?

Designers use 3D printers to quickly create product models and prototypes, but they are increasingly being used to manufacture finished products as well. Among the items created with 3D printers are footwear designs, furniture, wax molds for jewellery production, tools, stands, gift items, gadgets, and toys.

The automotive and aviation industries use 3D printers to produce parts. Artists can create sculptures, and architects can make models of their projects. Archaeologists use 3D printing to reconstruct models of fragile artifacts, including some antiquities that have been destroyed in recent years. Similarly, paleontologists and their students can duplicate dinosaur skeletons and other fossils.

Doctors and medical technicians can use 3D printing to create prosthetics, hearing aids, artificial teeth, and bone grafts. They can also replicate models of organs, tumors, and other internal body structures based on CT scans in preparation for surgery.

A good example is the Project Daniel, which uses 3D printing to create prosthetic hands and arms for victims of violence in Sudan. There are also 3D printers being developed that can layer cells to create artificial organs, such as kidneys and blood vessels, which are already in the research and development phase. 3D printing is also being used in forensics, for example to replicate a bullet lodged in a victim’s body.

Where to buy a 3D printer? And what should I pay attention to?

Most 3D printer manufacturers sell their products directly through the internet. Many online stores offer these devices, including companies that operate exclusively online. Such as Amazon, as well as those that also have physical stores.

However, it is worth checking the availability in a specific store on their websites, as not all points may have them. In some large cities, specialized shops with 3D printers are also being opened.

What are the prospects for 3D printing?

3D printers for homes and small businesses are already available on the market. Although they are still often seen as exotic and quite expensive devices. However, we can expect that in the next few years this situation will change. 3D printers will become more common in homes. We will find them in workshops, studios, home offices, and even in kitchens.

They may not be present in every household, but for those who have them, they will become indispensable. So far, most items created using 3D printers have had uniform interiors. We will start to see increasingly complex creations combining multiple materials and composites, as well as the ability to print electronics.

Today, if you lose the battery cover for your TV remote, you may be able to print a replacement. In the future, if you lose the remote itself, you may be able to print a whole new one.

Summary

3D printing undoubtedly opens up new horizons of possibilities for us in terms of creating objects. From simple gadgets to complex components and even artificial tissue.

This technology, once just a futuristic vision, is becoming increasingly accessible and practical for both professionals and amateurs. As 3D printers become more advanced, affordable, and easier to use, we can expect them to find a place not only in industry and medicine but also in our homes, offering countless possibilities for personalisation and innovation.

The future of 3D printing looks exciting, with the promise of further reducing production costs, improving accessibility, and expanding the range of printable materials.

What once seemed possible only in research laboratories or large manufacturing companies is now becoming achievable in the comfort of our own homes. 3D printing is changing the way we think about production, design, and repair, making the creation process more direct and personal.